~ Who I am ~

I became interested in guitars when I was a high-school student at the Industrial Institute in Cesena (Italy), a lovely town in the center of the Romagna region. My dedication to music became immediately very strong, I played many hours a day and I loved looking for guitars which satisfied me both on a musical and aesthetic level.

The idea of manufacturing musical instrument did not came immediately. Almost seven years went by from the moment I started playing to the one I designed my first musical instrument, and the circumstances which led me to lute manufacturing were many...

First and foremost I was very motivated: I was eager to possess an instrument which responded to my needs in every way possible. It seems trivial, but it is not: each human being is unique, and his tastes are unique. Musical instruments allowed everyone to became a musician, but they cannot be just how you want them to be. They will always be somewhat different from the instrument of your dreams.

The second circumstance was that my father has always had a deep passion for craftsmanship and since he has dedicated most of his life to woodworking he has acquired some knowledge which has always been pivotal to the realization of my projects. During my university career I manufactured many guitars with my father’s help and I kept studying and researching the lutherie manufacturing sector in order to design always better instruments. (I am very pleased to say that during the construction of my first guitar I could avail of precious tips from lute manufacturer Stefano Malusi, a very kind and accommodating person).

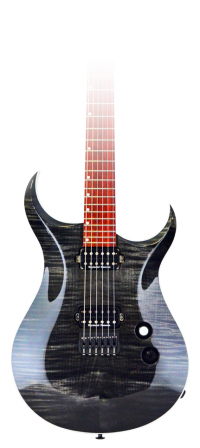

The day after I graduated, I literally locked myself in my workshop and I started to dedicate myself full-time to design and manufacture instruments which I wanted to be structurally impeccable, comfortable and aesthetically pleasing to the eye. Initially I dedicated special attention to the aesthetic side of the guitar, since I was very conscious of its importance in a musician’s mind. I inevitably stumbled upon too often understated details, which instead have a great relevance. When a musician is looking for a new musical instrument he often takes into first consideration the aesthetic side (hardware, brand, endorsers), leaving aside the aspects that will mainly influence the use of the instrument itself, such as: width, thickness and shape of the handle, radius of the fretboard, length of the scale, hight of the strings, material of the frets and constructive materials in general. For example, a person with a small hand will play way better and easily an instrument with a short scale (less than 63 cm), a slim neck (less than 20 mm from the first fret) and not too wide (for example 41 mm of width from the capo), compared to a bigger scale and a neck which do not fit his stature.

The importance of the wood type, especially for the neck, is pivotal in order to reach the desired sound. For now I leave out very important issues such as the choice of the material for the frets (I use almost exclusively stainless steel frets) and I ask you to please visit the dedicated page.

Every step of the guitar manufacturing process is performed by myself using both old tools, such as gouges, files, blades, and more modern and precise tools such as grader, presses, laser, milling cutter and numerous tools ordered and studied to execute precise works.

Cutting the frets position, for example, is not a process to be executed using a set square and a pencil; the required precision and perpendicularity of the cuts makes it almost essential to have a special tool to make the working process shorter, less expensive and demanding.

In my opinion it is crucial to understand which space to dedicate to art and creativity and which space to dedicate exclusively to technology.

I personally try to create harmony between the two sides, in order to reach what I think is the best result in terms of aesthetic beauty, uniqueness and precision. In my opinion this is the present and the future of musical instruments manufacturing and follows a very different path from the one chosen by big brands, often attracted by the low cost manufacturing of third world countries and (often) offering economic and largely advertised products.

My idea consists in wanting to adapt the instruments to the musician and not the contrary. I offer a custom service in a world where everything and everyone is standardized and cataloged. For these reasons I decided to manufacture every work exclusively by hand, to deliver to my clients an instrument which will possess the value which only a human hand is able to provide.

Olmo Bosi

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)