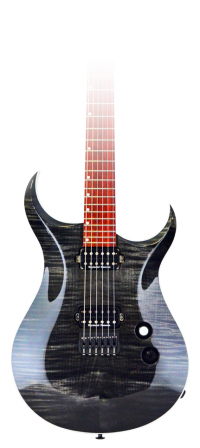

~ Custom ~

Arda is a Custom Shop in its most sublime sense: there are no limits to the client’s possibility of choice. The neck, the body, the hardware, the types of wood and the finish respond totally to the client’s desire. In fact he will be able to create his instrument without any compromise. I personally believe that he who decides to have a custom handmade guitar built should have a clear idea of what is best for himself. To a musician a handmade musical instrument must be the top of luxury, something which has nothing to do with the industrial productions he is used to. I would like to point out that I have no prejudice regarding factory guitars. In fact I believe they help the musician in his path since they are so plentiful and allow him to perfectly understand the characteristics he finds more comfortable or unpleasant. I believe it is important that a guitar player who wants to have a custom instrument built plays (or has been playing) numerous guitars in order to understand what is the best neck for him, the pickups and the sound he likes best, and all the details he would otherwise not have given importance to (It is definitely not pleasant to have a guitar built and then find out that an instrument with other characteristics is way more comfortable). Once the client chooses the best characteristics, we will start finding out how to blend them and improve them in the custom instrument. A musician who does not want to create a new shape can use a pre-existing model as a starting point and then enrich it with characteristics he would not find in an industrial guitar. Every step of the production process of an Arda instrument is executed with exceptional precision and with no compromises (contrary to what the industry does): attention to details is pivotal and the manufacturing process is finished only when everything proves to be impeccable.

Many luthiers make a list of the materials and hardware they use; I do not feel the necessity of doing it: if the musician wants a type of wood or a component which I do not already have in my workshop I will order it; the possibilities of customization must be endless (this is why every instrument is strictly handmade by me).

That said, there are a series of characteristics which I think are very important in order to have a quality instrument. Even though they are absolutely not compulsory, I would like to advice them since I believe they are an enrichment in both practical and quality terms.

I only use well seasoned woods (and they are numerous, like I said in the page regarding the technical characteristics of each instruments. Minimum time of seasoning is 24 years).

Every nut I use on my instruments is created at the moment from the rough material and completed on the guitar, for a perfect result regarding the spacing and the strings hight. The nut has an important role in the quality of the sound (for the stripped strings) and in keeping the tuning stable (every nut I make is studied to have less contact possible with the string allowing them to vibrate freely and reduce friction).

Truss rod

In my guitars I only use double action truss rods, and I install them with the rod resting in the channel in the neck. This allows me to remove less material near the headstock. The only difference from the standard is the direction of rotation at the time of adjustment (clockwise to decrease the force against the string tension, counterclockwise to increase the force against the string tension).

It would not make sense to manufacture a guitar by hand using poor quality components, so all I will say is that I use exclusively top quality hardware.

Contrary to what big firms (and some manufacturers) do, I use the same type of base and finish (a paint producer once suggested me to use a polyester base to make the work quicker, but I refused this option). So, if I use a polyurethane finish, I will use a polyurethane base (except if I receive different specifications from the client). I am always looking for techniques to improve and decrease the finish layer (not to speed the process up) and right now the final thickness is the minimum requirement to guarantee an impeccable aesthetic result.

As you can see from the pictures, I make almost every neck with no heel, providing a harmonious shape to the junction between the handle and the body. This gives the instrument a better aesthetic value and the comfort of a neck-thru.

The necks of my guitars are reinforced with two 5 or 6 mm stainless steel bars placed under the fretboard from the 12th to the 21st fret (I have seen many guitars ruined because of the structural failure of the handle in the portion following the junction with the body and I have decided to prevent the problem reinforcing the handle in this sensitive spot, giving it better stability). As an alternative it is possible to substitute the steel bars with longer graphite bars (recommended especially for extremely slim handles).

Almost all of my guitars have a neck laminated with the best woods and the best cuts in order to increase its stability and decrease the risk of deformations in the future.

I manufacture every headstock with the volute in order to provide better stability (which equals also to a lower probability of breaking in case the guitar falls to the ground), better sustain and to increase the quality of the instrument.

Apart from rare exceptions, on my guitars I use exclusively stainless steel frets, since they offer many advantages:

- Greater hardness: steel is way harder than the alloy commonly used to create frets, so they last way longer. None of us plays in a uniform manner on the fretboard, so if we own a guitar with common Nickel silver frets, they will wear out in an irregular manner creating a scattered loss of intonation. Nonetheless, with a slightly superior initial cost (stainless steel frets cost a bit more and require more work) the customer will obtain a guitar which won’t need future adjustments and substitutions, allowing him to save hundreds of euros.

- Better comfort: stainless steel frets are incredibly smooth and they facilitate the execution of string bending.

- Impact on the sound: producers of high-quality bridges glorify their stainless steel saddles. The same rules apply to frets. The string vibrates between two points (the location of the fret and the fret itself) so if we choose steel locations in order to make the sound brighter, we almost inevitably must opt for steel frets.

- Better aesthetic impact: stainless steel frets are shiny and they stand out more when they come in contact with the wood of the fretboard, increasing its elegance (obviously this is a matter of personal taste).

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)